4-Color vs 6-Color Printer Slotter Die Cutter Machines: What is the Difference?

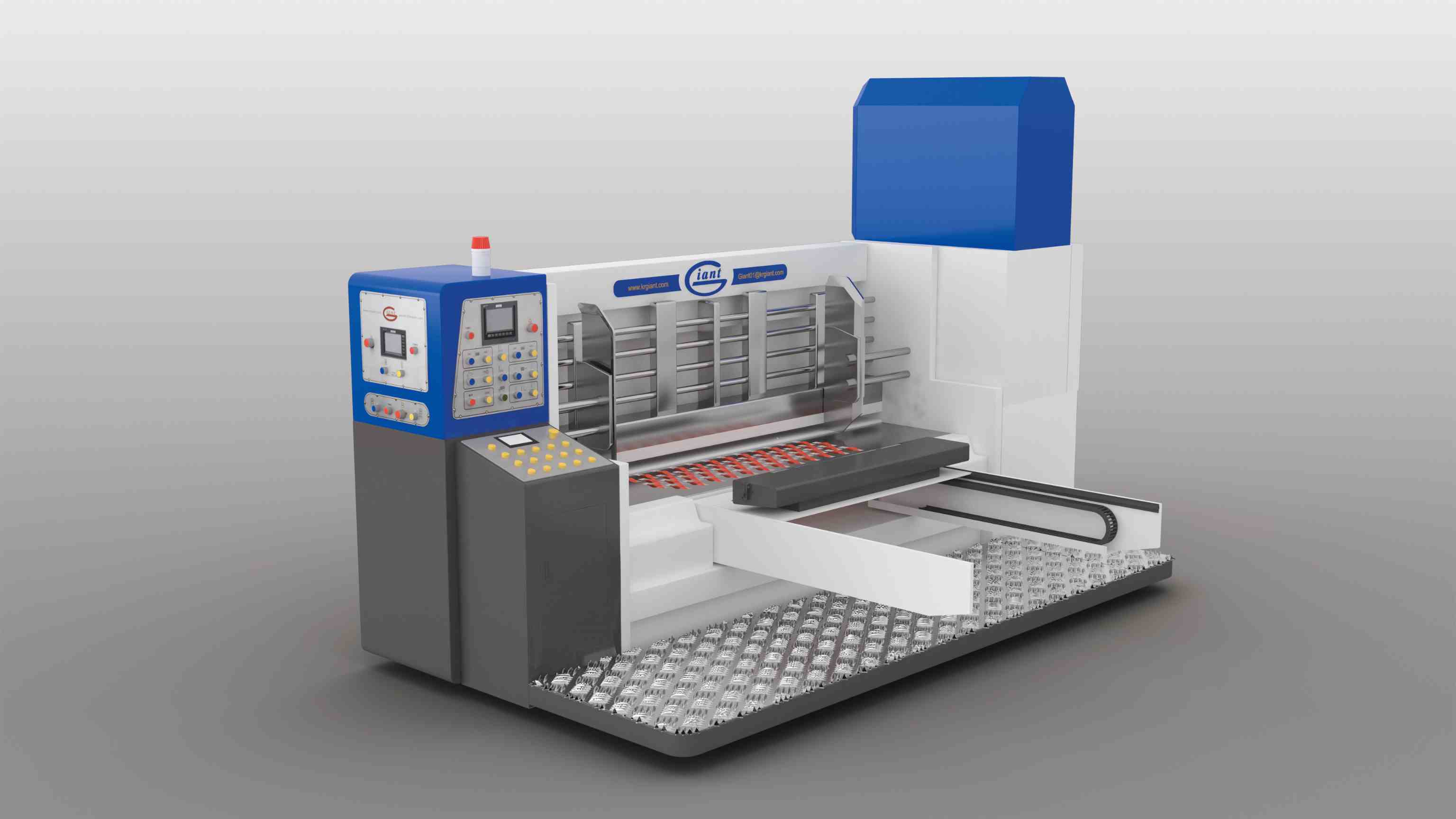

In today's corrugated packaging industry, the printer slotter die cutter machine is one of the most critical pieces of equipment for carton manufacturers. It integrates flexographic printing, slotting, and die cutting into a single production line, enabling efficient and consistent box manufacturing.

As customer expectations continue to rise—especially for branding, customization, and faster delivery—manufacturers are increasingly asking one important question:

What is the real difference between a 4-color and a 6-color printer slotter die cutter machine, and which one should I choose?

Although the difference may sound simple on the surface, the number of printing colors affects much more than appearance. It directly impacts production flexibility, target markets, operating costs, and long-term competitiveness. This article takes a deep look at 4-color vs 6-color printer slotter die cutter machines, helping you make the right decision based on real production needs.

What Is a Printer Slotter Die Cutter Machine?

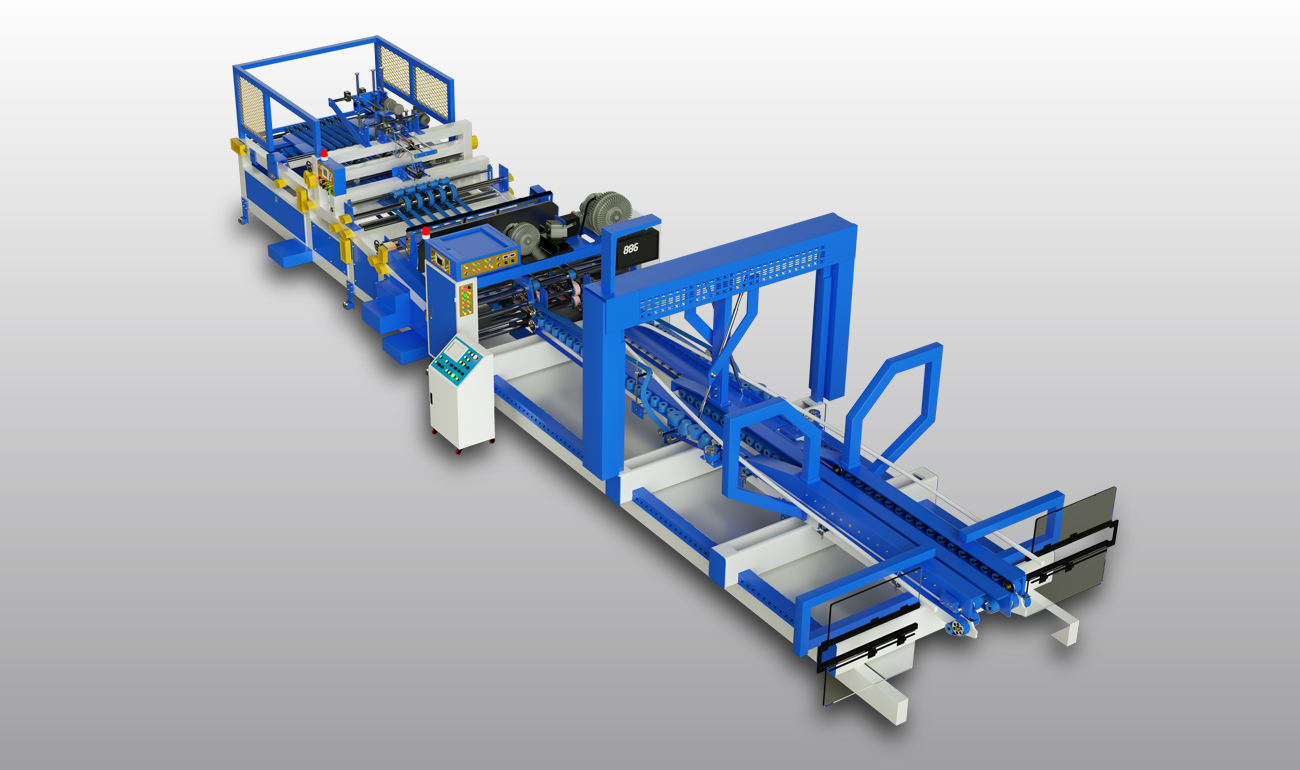

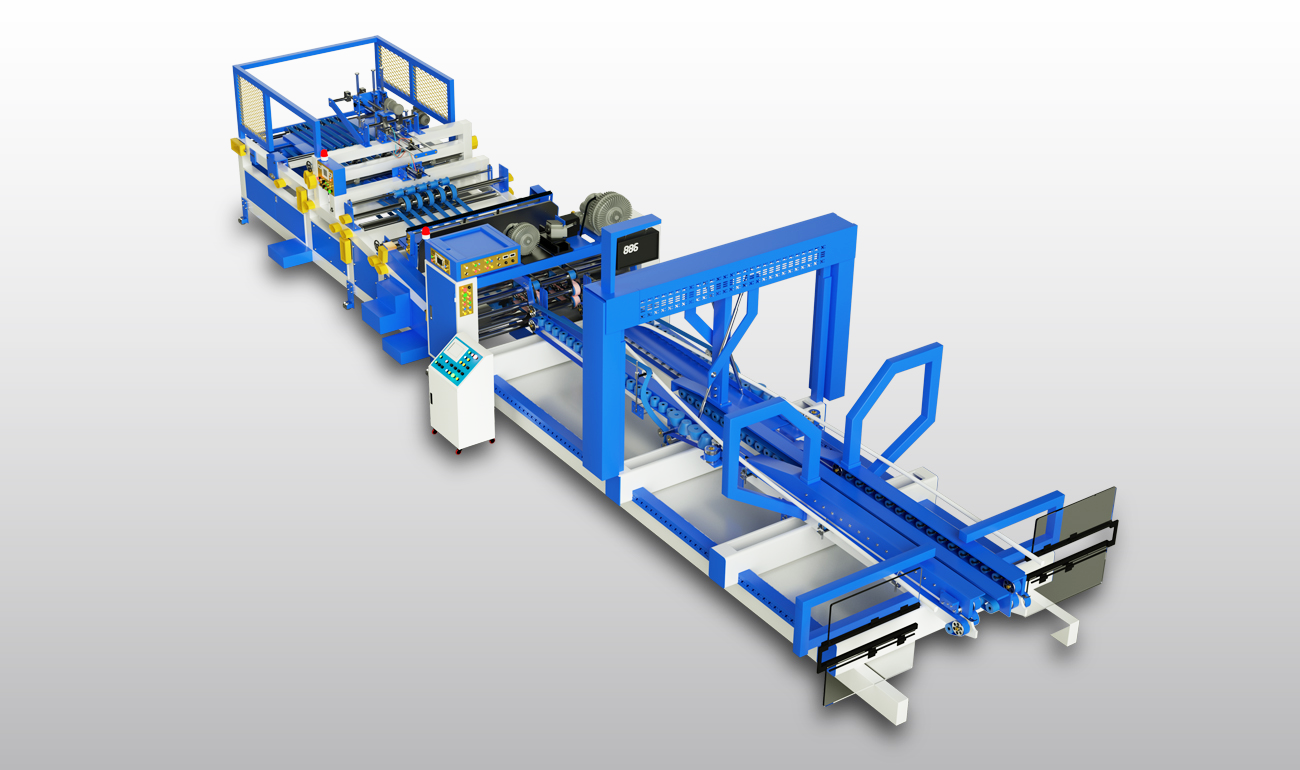

A printer slotter die cutter machine is a core system used in corrugated box production. It typically performs several processes in one continuous workflow, including sheet feeding, flexographic printing, slotting, corner cutting, die cutting, and stacking.

These machines are widely used to produce regular slotted containers, die-cut cartons, and customized corrugated packaging for industries such as logistics, e-commerce, food and beverage, electronics, and retail.

One of the most important configuration choices is the number of printing units, with 4-color and 6-color machines being the most common options in the market.

Understanding 4-Color Printer Slotter Die Cutter Machines

A 4-color printer slotter die cutter machine is equipped with four independent flexographic printing units. In most cases, these are used for CMYK printing or for four spot colors, depending on customer requirements.

This type of machine is extremely popular among carton plants focused on standard corrugated packaging. It is well suited for printing logos, text, barcodes, handling symbols, and basic graphics on brown or white corrugated board.

From a production perspective, 4-color machines are known for their stability, efficiency, and relatively simple operation. They are ideal for long production runs where designs do not change frequently and visual complexity is limited.

For many manufacturers, a 4-color printer slotter die cutter machine offers an excellent balance between performance and investment cost.

Understanding 6-Color Printer Slotter Die Cutter Machines

A 6-color printer slotter die cutter machine adds two additional printing units, allowing for greater design freedom and higher visual quality.

With six printing colors, manufacturers can handle more complex artwork, incorporate special spot colors, improve color saturation, and achieve smoother gradients. This makes 6-color machines particularly suitable for branded packaging, retail cartons, and high-end corrugated boxes.

As packaging increasingly becomes part of a brand's marketing strategy, the demand for visually appealing cartons has grown rapidly. In this context, 6-color printer slotter die cutter machines are often seen as a strategic investment for manufacturers targeting premium customers.

Key Differences Between 4-Color and 6-Color Machines

Printing Capability and Design Flexibility

The most obvious difference lies in printing capability. A 4-color machine is perfectly capable of handling functional and cost-effective packaging designs. It works well for transport cartons and industrial packaging where clarity and consistency matter more than visual impact.

A 6-color machine, on the other hand, allows for more detailed graphics and stronger brand expression. Additional colors make it easier to match brand standards and create eye-catching designs, especially for retail and e-commerce packaging.

Target Markets and Applications

The choice between 4-color and 6-color machines often reflects a factory's target market.

Manufacturers using 4-color machines typically focus on logistics cartons, bulk packaging, and cost-sensitive orders. These customers value reliability, fast delivery, and competitive pricing.

Manufacturers with 6-color machines are better positioned to serve brand-driven clients, retail packaging projects, and customized box designs. These orders usually offer higher profit margins but also require higher print quality and tighter quality control.

Production Efficiency and Order Structure

In terms of speed, modern automatic printer slotter die cutter machines are designed to maintain high output regardless of the number of colors. However, production efficiency depends heavily on order structure.

4-color machines are especially efficient for long runs with repetitive designs, where quick setup and stable operation are key advantages. 6-color machines perform best in environments with frequent design changes, smaller batch sizes, and higher customization requirements.

The right choice depends less on machine speed and more on how your production schedule is structured.

Cost, Investment, and ROI

Cost is always a major consideration when investing in corrugated packaging machinery.

A 4-color printer slotter die cutter machine generally requires a lower initial investment and has lower operating costs. For factories focused on standard cartons, this often leads to a faster return on investment.

A 6-color printer slotter die cutter machine comes with a higher purchase price, but it also opens the door to higher-value orders. Over time, the ability to handle premium packaging projects can significantly improve overall profitability.

Rather than focusing only on machine price, manufacturers should evaluate long-term ROI, including order value, customer retention, and future market opportunities.

Operation, Skill Level, and Maintenance

Another difference lies in daily operation.

4-color machines are relatively easy to operate and maintain. They require fewer color adjustments and simpler setup procedures, making them suitable for factories with limited operator experience.

6-color machines demand more precise color registration and stricter process control. While this requires a higher skill level, modern automation systems have made operation far more user-friendly than in the past.

With proper training and maintenance, both machine types can deliver stable, high-quality results.

Which Machine Is Right for Your Factory?

Choosing between a 4-color and a 6-color printer slotter die cutter machine should be based on your current business model and future growth plans.

If your factory mainly produces transport cartons, focuses on cost efficiency, and runs large volumes of similar designs, a 4-color machine is often the most practical choice.

If your customers demand stronger branding, custom graphics, and retail-ready packaging, a 6-color machine provides the flexibility needed to compete in higher-end markets.

Many growing manufacturers choose to start with a 4-color machine and later expand to 6-color capacity as customer demand evolves.

How We at Giant View 4-Color vs 6-Color Choices

At Giant, we work closely with corrugated box manufacturers across different markets, and we understand that equipment decisions are never one-size-fits-all.

From our experience, the most important factors are production stability, print accuracy, and long-term reliability—not simply the number of colors. That is why we focus on designing printer slotter die cutter machines that can be configured flexibly, whether a customer chooses a 4-color or a 6-color setup.

We believe the right machine is the one that fits real production needs, supports future growth, and delivers consistent performance over many years of operation.

Future Outlook: 4-Color vs 6-Color in 2026 and Beyond

Looking toward 2026 and beyond, several trends are influencing equipment selection. E-commerce growth, shorter product cycles, and increasing demand for branded packaging are driving interest in higher-color printing solutions.

At the same time, 4-color printer slotter die cutter machines will continue to play a vital role in corrugated packaging due to their efficiency, reliability, and cost-effectiveness.

Rather than replacing one another, 4-color and 6-color machines will continue to coexist, each serving distinct production needs within the industry.

Conclusion

The difference between 4-color vs 6-color printer slotter die cutter machines is not about which option is universally better, but about which one aligns with your factory's strategy.

4-color machines excel in efficiency, simplicity, and stable high-volume production. 6-color machines offer greater design flexibility, higher-value applications, and stronger branding potential.

By understanding these differences clearly, manufacturers can invest with confidence and build a more competitive corrugated packaging operation.