Rotary Die Cutter vs Flatbed Die Cutter: Which Is Better for Flexo Printing Machines?

In modern packaging and label production, flexo printing machines have evolved into highly integrated systems that combine printing, coating, laminating, and die cutting in a single production line. Among these processes, die cutting plays a critical role in defining final product shape, accuracy, and production efficiency.

Two of the most widely used die cutting solutions in flexographic printing are the rotary die cutter and the flatbed die cutter. While both are designed to cut printed materials into precise shapes, they differ significantly in structure, working principle, speed, flexibility, and ideal application scenarios.

This article provides a comprehensive comparison of rotary die cutters vs flatbed die cutters for flexo printing machines, helping converters, packaging manufacturers, and equipment buyers determine which solution best fits their production needs.

Understanding Die Cutting in Flexo Printing Machines

Die cutting is typically positioned inline or near-line with the flexo printing unit, allowing printed materials such as corrugated board, paperboard, labels, or flexible substrates to be cut, creased, or perforated without interrupting workflow.

In a flexo printing machine, a die cutter must meet several key requirements:

- High accuracy and repeatability

- Compatibility with continuous web or sheet feeding

- Synchronization with printing speed

- Ability to handle different materials and thicknesses

Both rotary die cutters and flatbed die cutters fulfill these requirements in different ways.

What Is a Rotary Die Cutter?

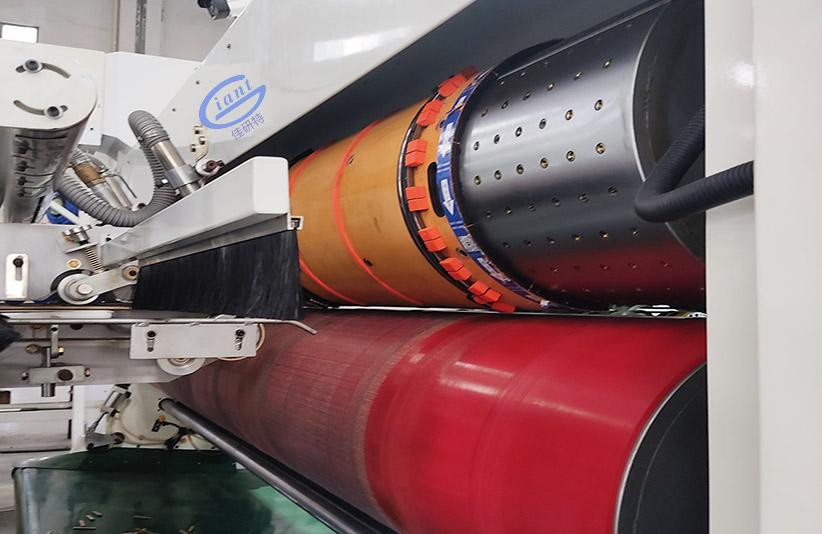

A rotary die cutter uses a cylindrical die mounted on a rotating drum that continuously cuts material as it passes through the machine. In flexo printing machines, rotary die cutters are usually installed inline, allowing printing and die cutting to occur in a single pass.

Key Characteristics of Rotary Die Cutters

- Continuous rotary motion

- High-speed operation

- Minimal material stop or start

- Excellent registration with flexo printing units

Because of their continuous operation, rotary die cutters are especially suited for high-volume, high-speed flexo printing lines.

What Is a Flatbed Die Cutter?

A flatbed die cutter uses a flat die plate that presses vertically onto the material to cut it into shape. In flexo printing environments, flatbed die cutters are often used offline or semi-inline, particularly for shorter runs or more complex cutting requirements.

Key Characteristics of Flatbed Die Cutters

- Intermittent cutting motion

- High cutting pressure

- Greater flexibility for complex shapes

- Lower tooling cost in many cases

Flatbed die cutters are commonly used where precision and versatility are prioritized over speed.

Structural Differences Between Rotary and Flatbed Die Cutters

One of the most obvious differences lies in machine structure.

Rotary die cutters rely on precision-machined cylinders that rotate in perfect synchronization with the material feed. This structure allows seamless integration into a flexo printing machine and ensures continuous material flow.

Flatbed die cutters, by contrast, operate using an up-and-down press mechanism, requiring the material to stop briefly during each cutting cycle. While this enables higher cutting force, it limits overall production speed.

Speed and Production Efficiency

Rotary Die Cutter Performance

Speed is where rotary die cutters truly excel. Because the cutting process is continuous, they can easily match or exceed the printing speed of modern flexo printing machines.

Advantages include:

- Ideal for long production runs

- Minimal downtime between cycles

- Higher overall throughput

For packaging plants producing large volumes of cartons, labels, or flexible packaging, rotary die cutters significantly reduce unit production cost.

Flatbed Die Cutter Performance

Flatbed die cutters operate at slower speeds due to their intermittent motion. However, they compensate by offering:

- Strong cutting force

- Excellent accuracy on thicker or rigid materials

- Better handling of intricate designs

For small batches or specialty packaging, speed may be less critical than cutting precision.

Cutting Accuracy and Registration

In flexo printing machines, maintaining accurate registration between printing and die cutting is essential.

Rotary die cutters provide excellent repeat accuracy, especially in inline configurations where the die cutter is directly synchronized with the printing unit. This makes them well-suited for labels and packaging that require consistent repeat lengths.

Flatbed die cutters, while slower, often offer greater flexibility in design adjustments, making them suitable for products with varying layouts or frequent design changes.

Tooling Cost and Maintenance Considerations

Rotary Die Tooling

Rotary dies typically have:

- Higher initial cost

- Longer lifespan

- Better consistency over long runs

Although the upfront investment is higher, rotary die tooling often becomes more cost-effective in large-scale production.

Flatbed Die Tooling

Flatbed dies are generally:

- Lower in initial cost

- Easier to modify or replace

- Suitable for frequent design changes

This makes flatbed die cutters attractive for custom or short-run jobs.

Material Compatibility

Both systems can handle a wide range of materials, but their strengths differ.

Rotary die cutters perform best with:

- Paperboard

- Labels

- Corrugated board

- Thin flexible materials

Flatbed die cutters are often preferred for:

- Thick paperboard

- Rigid packaging

- Complex creasing and embossing

- Short-run specialty materials

Choosing the right die cutter depends heavily on substrate type and thickness.

Integration with Flexo Printing Machines

In modern production lines, integration is a key decision factor.

Rotary die cutters are highly compatible with inline flexo printing machines, allowing printing, die cutting, and stacking to occur in a single automated flow. This reduces labor costs and improves consistency.

Flatbed die cutters are more commonly used in offline or hybrid setups, where printed sheets are transferred to a separate die cutting station. While this adds handling steps, it increases flexibility.

Which Die Cutter Is Better for Flexo Printing Machines?

The answer depends on your production priorities:

- If your business focuses on high-speed, high-volume packaging, a rotary die cutter is usually the better choice.

- If your operation requires frequent design changes, complex shapes, or short production runs, a flatbed die cutter may be more suitable.

Many advanced manufacturers now combine both technologies across different production lines to maximize efficiency and flexibility.

Choosing the Right Solution: Practical Considerations

When selecting between rotary and flatbed die cutters for flexo printing machines, consider:

- Daily production volume

- Product variety

- Material thickness

- Budget and tooling costs

- Future expansion plans

Experienced equipment suppliers often help customers evaluate these factors before finalizing a solution.

The Role of Advanced Flexo Die Cutting Solutions

As flexo printing technology continues to advance, die cutting systems are becoming more automated, precise, and integrated. Leading manufacturers are now focusing on:

- Servo-driven die cutting units

- Quick-change die systems

- Improved registration control

- Reduced waste and setup time

Companies like Giant, with extensive experience in flexo printing and converting equipment, are increasingly developing integrated rotary die cutting solutions that align with modern production demands. By focusing on machine stability, precision engineering, and long-term reliability, such solutions help manufacturers achieve consistent quality while maintaining high output.

Conclusion

Both rotary die cutters and flatbed die cutters play essential roles in flexo printing machines. There is no universal ''best'' option—only the right solution for specific production needs.

Rotary die cutters stand out for speed, efficiency, and inline integration, making them ideal for large-scale packaging production. Flatbed die cutters offer flexibility and cutting power, serving short runs and complex designs exceptionally well.

By carefully evaluating production goals and working with experienced equipment providers like Giant, manufacturers can select a die cutting system that supports both current operations and future growth.